The Newest Technologies in the Machine Shop Cloud

You have certainly heard of cloud computing by now: placing your entire work product in the cloud allows access and collaboration by individuals located anywhere in the world where there is internet access. But can a machine shop operate in the cloud?

Not only can a machine shop operate in the cloud, to be competitive and to expand their customer base, it essential. A modernized machine shop is not fully up to Industry 4.0 standards if it is not working in the cloud.

IoT in the Machine Shop

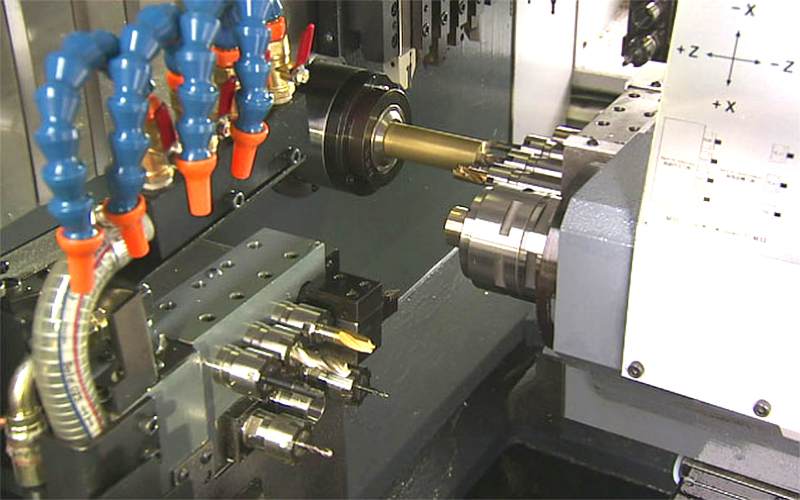

Okay, so nobody is going to actually try to set a hefty CNC machine on a literal cloud; but the data used by that CNC machine in the machine shop, will have to flow through the internet cloud if that shop is to be considered part of the Industry 4.0 group and the internet of things.

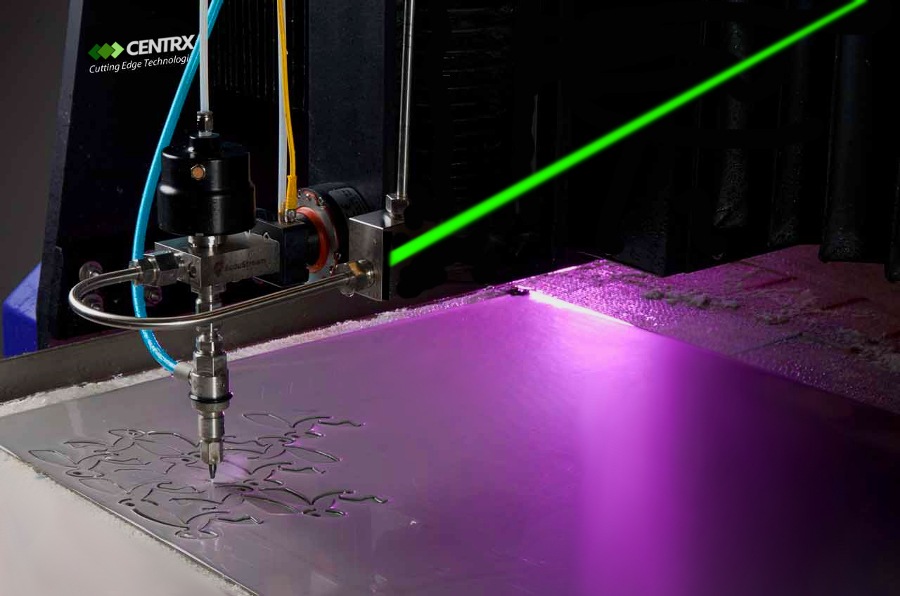

“The Internet of Things”, abbreviated as IoT, is a less familiar term to most people. The IoT is a network of devices, vehicles, buildings and, you guessed it, CNC machines, 3D printers, Waterjet Cutting Machines and so on.

Anything that consists of electronic control will, these days, also have a network connection. This network connection makes machine shop tools part of the IoT family.

IoT to Cloud

There are a great many advantages to have CNC and other machine shop tools connected to the cloud. Firmware and software updates to these machines are critical in maintaining efficiency and safety of machine operations. There may be feature and tooling library updates as well.

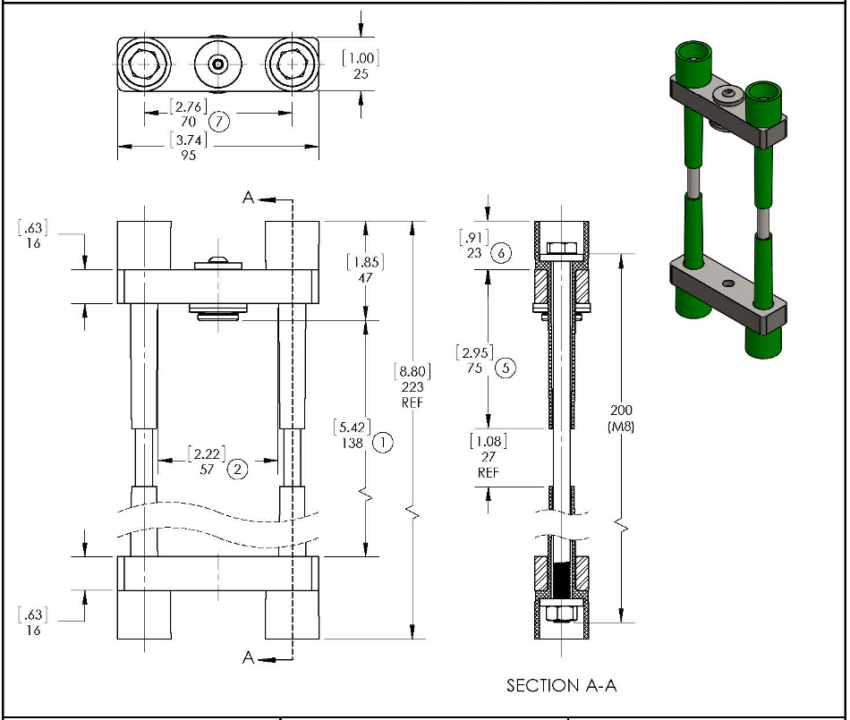

Another advantage to doing business in the cloud is having the ability for sharing designs with a client before, during and after machining to make sure all parties are on the same path. These designs may be schematics, blueprints, photos or any kind of documentation.

Cloud to Human

Having cloud access is more than connecting to the outside world. Having cloud access allows all the local machines to communicate with each other. They can share data as a workpiece is moved from one machine to another along its progress path.

Humans are the not obsolete in this era. The people operating the machines must be trained and proficient in the proper setup and operation of the machines. Real-time data displayed on remote or local touchscreen monitors allows operators to track the progress of a workpiece and monitor the status of the machine itself.

Machines showing tool wear, calibration errors or other potential problems are able to alert an operator to take the appropriate actions.

Having a cloud-based machine shop builds efficiency, safety and increases productivity while reducing costs by saving energy and reducing waste materials.

A cloud machine shop is a modern machine shop.

We provide industry leading Machine Shop products and standards in the Pittsburgh, Pennsylvania Area. And our customer service reflects the same. Give us a call today!