Latest Machine Shop Technologies

Centrx Inc. Your Machine Shop in Pittsburgh PA

Industry 4.0: have you heard of it? Machine shop technology evolves continuously over time, bringing us to the current, fourth era of the industrial revolution.

The era of steam and water powered tools was Industry 1.0. And Industry 2.0 issued in the era of electricity. Industry 3.0 welcomed computers into the machine shop. Industry 4.0 takes on the internet.

Around 2011 is when we officially entered industrial revolution 4.0 . Far more reaching than just connecting a computer to a drilling machine or lathe, now the machines are networked to each other within the machine shop, to the front office and globally, if you want.

Collection of Data

With internet connectivity, thousands of data points are continuously collected, whether the machine is in operation or standing idle. All this data is used in many ways: from reducing energy consumption, reducing waste of materials and creating a safer work environment.

Data on each project can be shared across the room or across the world where teams may evaluate and modify designs prior to manufacture. Computer simulations of machining a part may catch potential problems during the machining process.

Modern Machine Shop Tools

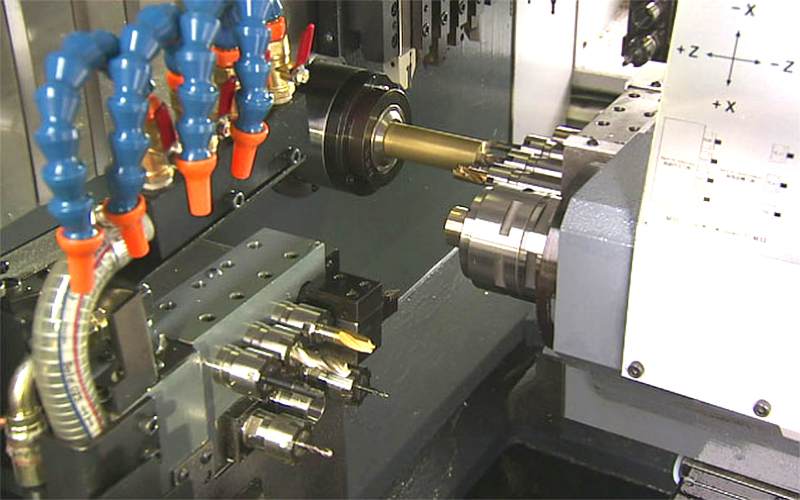

So many tools of the trade within the machine shop are automated; for example, robot drilling. With multiple drill bits loaded, a robotic drilling machine can work at a higher RPM rate and with much greater accuracy.

A Fiber Laser can weld, engrave or create cuts that are precise and intricate in sheets of metal. Using optical fiber allows the machine to be compact because the fiber is flexible and can move with the cutting head to deliver the 5000 watts, or more, laser beam.

Selective Laser Melting brings 3D printing to a whole new level. Metallic powder is placed on the 3D print bed, melted with a laser and then another layer of powder is placed on that and melted. Layer by layer a 3D metal part is formed. From there it may be machined smooth by the same 3D printer or taken to another machine for finishing.

Perhaps the one machine in the machine shop which saves the most time is the 5-Axis CNC machine. Not only do the machining tools move, but so does the support bed. These 5-Axis machines cut along the X, Y and Z axis, but can also orbit around each axis, creating X with an A orbit, Y with a B orbit and Z. Of course, there is a sixth axis of C orbiting around a Z axis, but that is not very useful in production and is rarely found in a CNC machine.

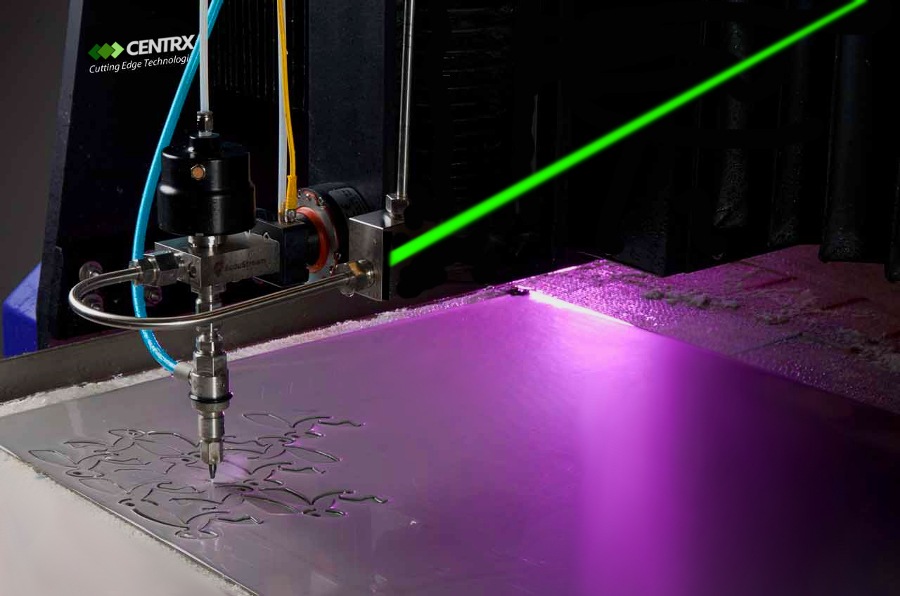

Water Jet Cutting

Water Jet cutting may not sound as exciting as your typical CNC machine but is very useful. Under high pressure, almost 60,000psi, a fine stream of water passes through a small nozzle, such as a 0.007-inch diameter, producing a high velocity stream which can cut with fine precision soft materials, such as thin plastic or paper. Denser materials, such as various metals, require an abrasive powder, like garnet, to be introduced into the stream for cutting.

The use of Water jet cutting is quieter than other processes and does not generate any heat. When a part is being fabricated, heat can introduce micro-fractures. The end result produces an accurate and smooth finish.

We provide industry leading Machine Shop products and standards in the Pittsburgh, Pennsylvania Area. And our customer service reflects the same. Give us a call today!