How SCR Heat Sinks Protect Power Controllers

When deciding on components for your major electronic systems, it is vitally important that excess energy and heat is properly expelled from your system to prevent overheating and catastrophic meltdown.

Initially developed in the 1950s, Silicon controlled rectifier (SCR) power controllers, sometimes referred to as a thyristor, are capable of producing several megawatts of energy and are widely used in a variety of industrial processes in the manufacturing industry.

What is an SCR System?

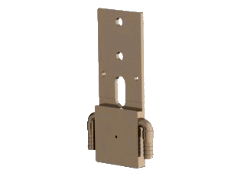

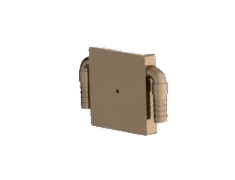

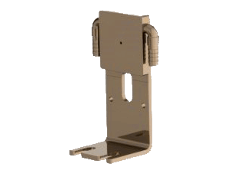

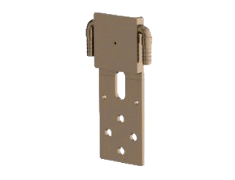

An SCR System is a relatively inexpensive means of regulating power supply, and are more energy efficient than your typical variable transformer or saturable core reactor. It consists of four primary parts: the semiconductor power device (the SCR itself), firing circuit, SCR Heat Sink, and various protective circuits.

SCR Systems tend to have high reliability and extremely low maintenance in comparison to similar options, and are capable of extremely rapid response times. They also provide a greater degree of customizability, such as the option to limit currents and voltages.

Gain Unlimited Access to Downloads of SCR Clamp and SCR Heat Sink Drawings and Specifications. Use Centrx’s Online SCR Clamp Configuration Tool and more!

How Does an SCR Heat Sink Protect My Investment?

SCR Systems produce vast amounts of heat in a very small physical space: the emit an average of 1.5 watts of heat energy per ampere. Yet, studies have found that the reliability of SCRs decreases by 50% for every 10⁰ in semiconductor temperature. Given the devastating effect that high temperatures can have on SCR functionality, it is incredibly important to provide a means to dissipate excess heat thoroughly.

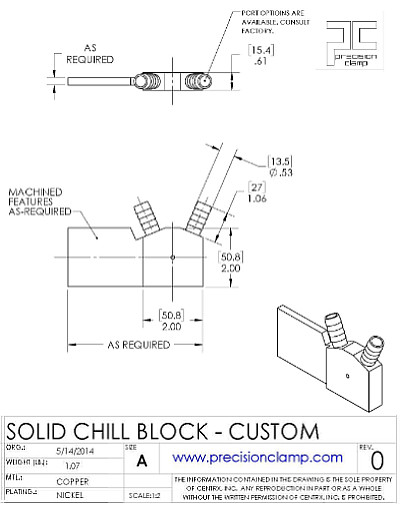

Low-wattage electronics can typically be rigged to dissipate excess heat naturally, and systems with higher energy expenditures often utilize fans and aluminum SCR Heat Sinks to maintain effective internal temperatures. However, when SCR controllers with very high current ratings are used, a liquid cooled SCR Heat Sink is required to dissipate heat and maintain functionality.

What Makes Centrx’s SCR Heat Sinks Different?

Lower Operating Temperatures

Through the use of Liquid-Cooled SCR Heat Sinks, your company can dissipate even greater amounts of heat, thereby reducing performance issues and extending the life of your SCR Systems. Centrxs’ SCR Heat Sinks are able to do this by using a liquid medium, which more effectively captures and cools excess heat, removing it from the cabinet and into an ambient space.

Smaller Width

Centrx’s SCR Heat Sinks are the thinnest in the industry, which is vitally important when they are being used in large amounts. Centrx’s clients frequently require the use of several SCR Heat Sinks operating together in order to dissipate large amounts of heat and energy from high-powered electronic equipment. By using the thinnest SCR Heat Sinks currently in production (30-40% thinner than the competition!), you can dissipate more heat and and energy while conserving space and avoiding the need to modify current equipment to include even greater cabinet space.