The Latest Machine Shop High-Tech Advancements

Latest Machine Shop Technologies

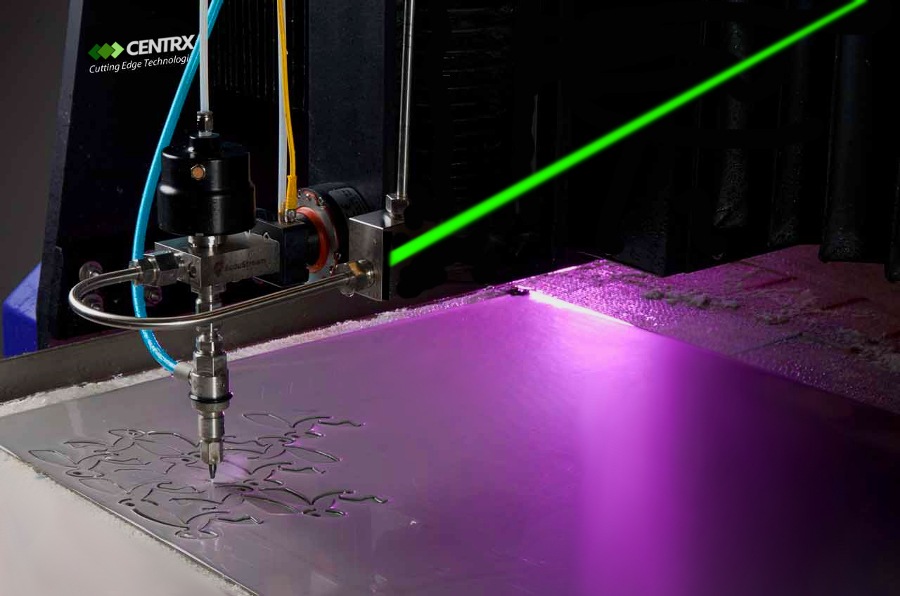

Centrx Inc. Your Machine Shop in Pittsburgh PA

Industry 4.0: have you heard of it? Machine shop technology evolves continuously over time, bringing us to the current, fourth era of the industrial revolution.

The era of steam and water powered tools […]