Machine Shop Quality Assurance

SCR Clamp Quality Assurance

If you are in the market for your next manufacturer of SCR Bar Clamps, you know how important it is to work with a manufacturer who takes SCR Clamp Quality Assurance seriously. Failure to guarantee the quality of your manufactured products can lead to catastrophic failure of these components while they are in use. And this may cause your production line to ground to a halt and lead to dozens of lost man-hours.

Even worse, you will now have to research new component manufacturers at a time when you need reliable components the most.

Read on to learn more about our commitment to quality and reliability in the production of our SCR Clamps.

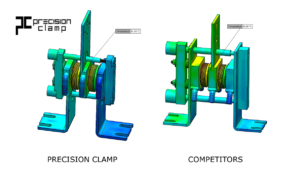

SCR Clamp Product Design

Centrx’s focus on quality assurance begins long before an item enters production.

Before we approve a new design each new unit goes through a rigorous testing process.

First, the product is designed using feedback from our customers and professionals who work with our devices on a daily basis.

This allows us to take into account concerns and issues with current models and to design SCR Clamps made to handle any problem in the field.

Prototyping

Once the product design is complete, our team creates a custom prototype, to be tested in both laboratory and real-world conditions in the field.

If problems arise during this testing period, our team of engineers returns to the drawing board. The entire design is reconfigured until the problem is resolved.

This new design is then formed into a prototype and undergoes another set of the same rigorous tests. Some companies will skimp on their product design testing and costs, but this can lead to major problems down the line. This is why Centrx is committed to undertaking thorough pre-production testing on all of our new designs.

SCR Clamp Production Process

Our production processes are also created by the same engineering team that designed and tested the initial prototype.

By working with those engineers who are intimately familiar with our products and designs, we can ensure that any potential problems in the production line are addressed in the planning stage.

In addition, our entire team of production line workers are well-versed in the production process, and any areas that are susceptible to problems, and have the knowledge to proactively identify areas of concern.

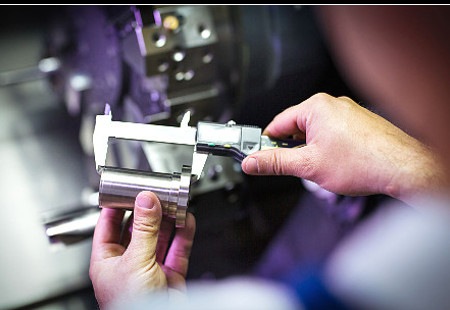

In addition, our machines are incredibly well-maintained and accurate, meaning that they will produce more consistent products in a timely and cost-effective manner.

Post-Production Testing

The final step in Centrx’s quality assurance process is post-production testing. We take quality control very seriously. This allows us to guarantee the quality and performance of our components each and every time.

Materials

Lastly, Centrx only uses the finest input materials in the production of our SCR Clamps. Many companies will skimp out on the quality of their base materials, but this increases the likelihood of component failure, reduces the component’s effective service life, and ultimately costs your business more money in the long run.

Further information on manufacturing quality assurance in general can be found here