Modern Manufacturing

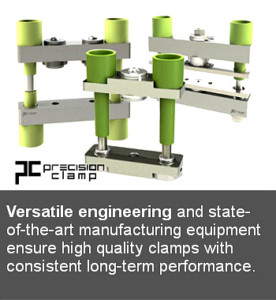

At Centrx, our company’s leadership is committed to staying abreast of, and implementing, developments in modern manufacturing technology that allows us to improve the performance and reliability of our SCR Heat Sinks and SCR Clamps.

Manufacturing technologies and practices have changed dramatically over the past century, with new developments such as the use of computers, data analytics, lean manufacturing processes, and increased education and training of supervisors and line workers. This article will describe some of the recent changes in modern manufacturing, and will explain how Centrx has implemented these changes in our production process.

What’s New

Modern manufacturing is undergoing the most extreme set of changes and developments that the industry has witnessed since the Industrial Revolution in the early 1800s. The addition of advanced computers, rigorous data analyses, and automated processes are dramatic changes from the sort of assembly line found in most factories just decades ago.

Modern manufacturing is undergoing the most extreme set of changes and developments that the industry has witnessed since the Industrial Revolution in the early 1800s. The addition of advanced computers, rigorous data analyses, and automated processes are dramatic changes from the sort of assembly line found in most factories just decades ago.

These developments have both positive and negative consequences: industrial products, such as our products, can produced at a fraction of the cost, with greater speed, accuracy, and reliability. However, as computers have become more advanced and processes have increasingly become automated, many workers are being left behind as the need for labor decreases exponentially.

Lean Manufacturing

Lean Manufacturing, sometimes known as Lean Production, is an approach to manufacturing that seeks to reduce and eliminate waste. In the manufacturing world, waste can mean anything from unused materials, excess energy consumption or waste, unnecessary man hours, and inefficient processes. The idea of lean manufacturing was taken from the Toyota Production System in the 1990s. According to the Toyota philosophy, there are seven wastes that are to be eliminated: transportation, inventory, motion, waiting, over-processing, over-production, and defects. Centrx follows the lean manufacturing ethos in the production, which means increased savings for you: the consumer.

Reliability

With the introduction of advanced computers into our SCR Heat Sinks and SCR Clamps manufacturing processes, we can ensure even greater accuracy in the manufacturer of these parts. In addition, this new technology allows us to produce identical products with miniscule variances in performance, reliability, and service life. This means that you can have even greater confidence in Centrx’s long track record of producing quality products that exceed their service life every single time.

Safety

At Centrx, one of our primary concerns is the safety of our employees. Prior to recent advances in manufacturing technology, industrial manufacturing was a dangerous job with the potential for accidents and injuries. However, since the implementation of modern manufacturing processes the safety of our employees has been ensured.